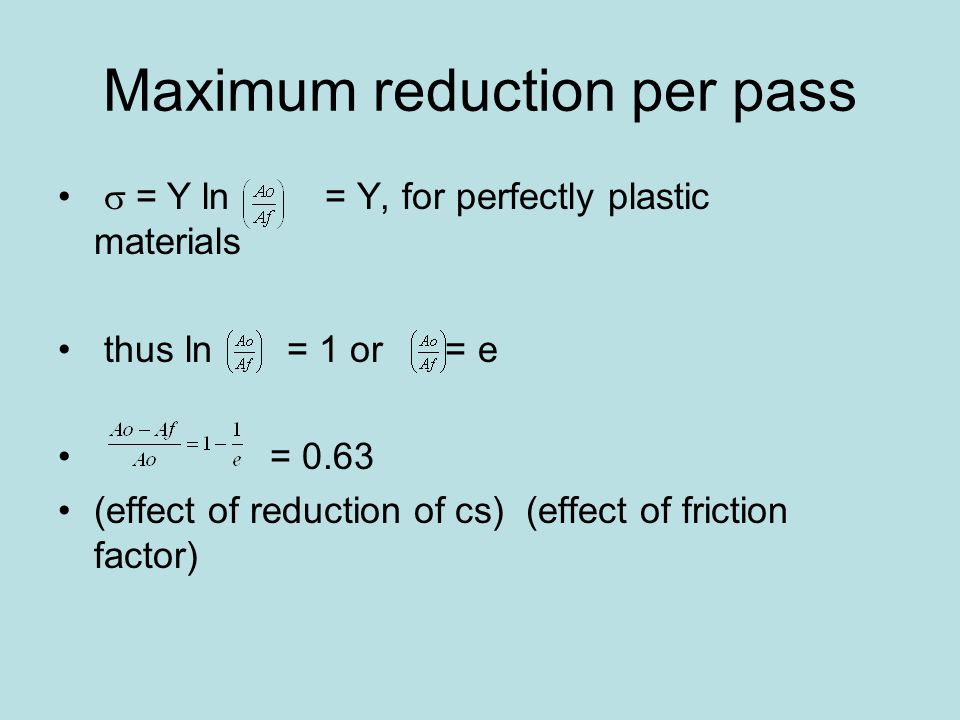

The maximum reduction in area of wire is less than 45 in one pass. This reduction of section is at the same time balanced by.

During drawing operation each time the wire goes trough a die.

. Wire Drawing Process Reduction Ratio Of The Wire R Can Be Download Scientific Diagram 2aπ Surface area 534 sq. Incoming wire diameter mm inch Øout. The process of wire drawing changes material properties due to cold working.

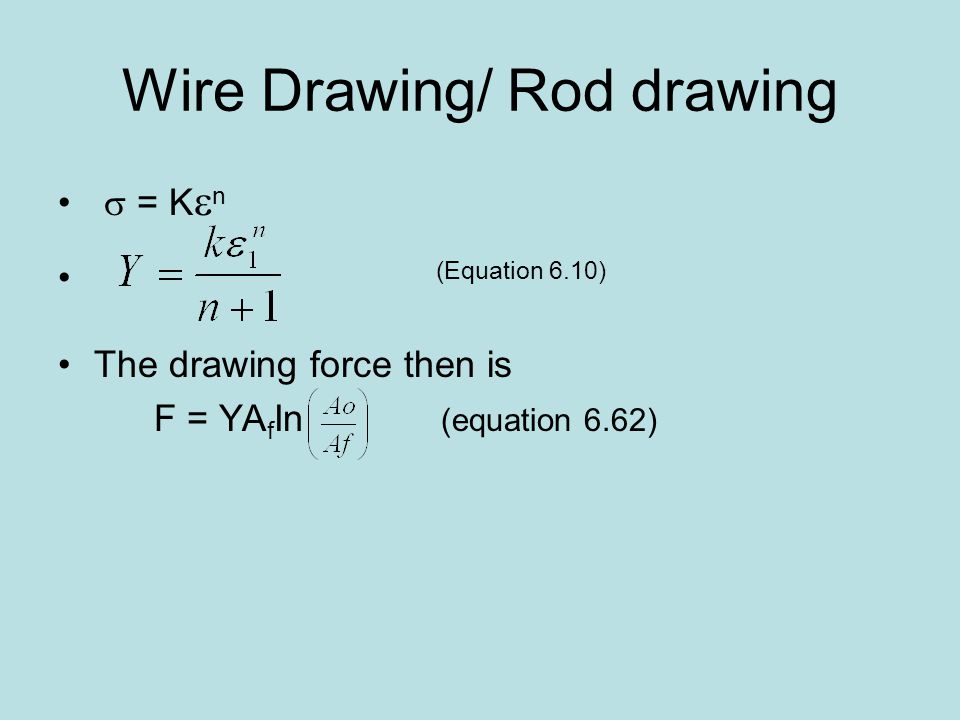

The approach angle where the actual reduction in diameter occurs giving the half die angle α The bearing region produces a frictional drag on the wire and also remove surface damage. 2a Wire diameter increases as drawing dies wear in actual produc-tion. Approximate expression for drawing force can be written based on plastic work or strain energy.

Defect can also develop in the drawing of rod of wire and of tubes. The percentage reduction of area r is given by the following equation r 100 x Ao AfAo Where Ao is the initial area and Af is the final area of the wirerod after drawing. Wire Drawing Reduction Formula.

Slip Roll Speed b Wire Speed d Roll Speed b DIE MATERIAL SELECTION TABLE. Therefore based on constancy of volume wire speed will decrease as the dies increase in size. A draw reduction is a multistep process in which the surface area of the original blank is displaced through a series of drawing operations.

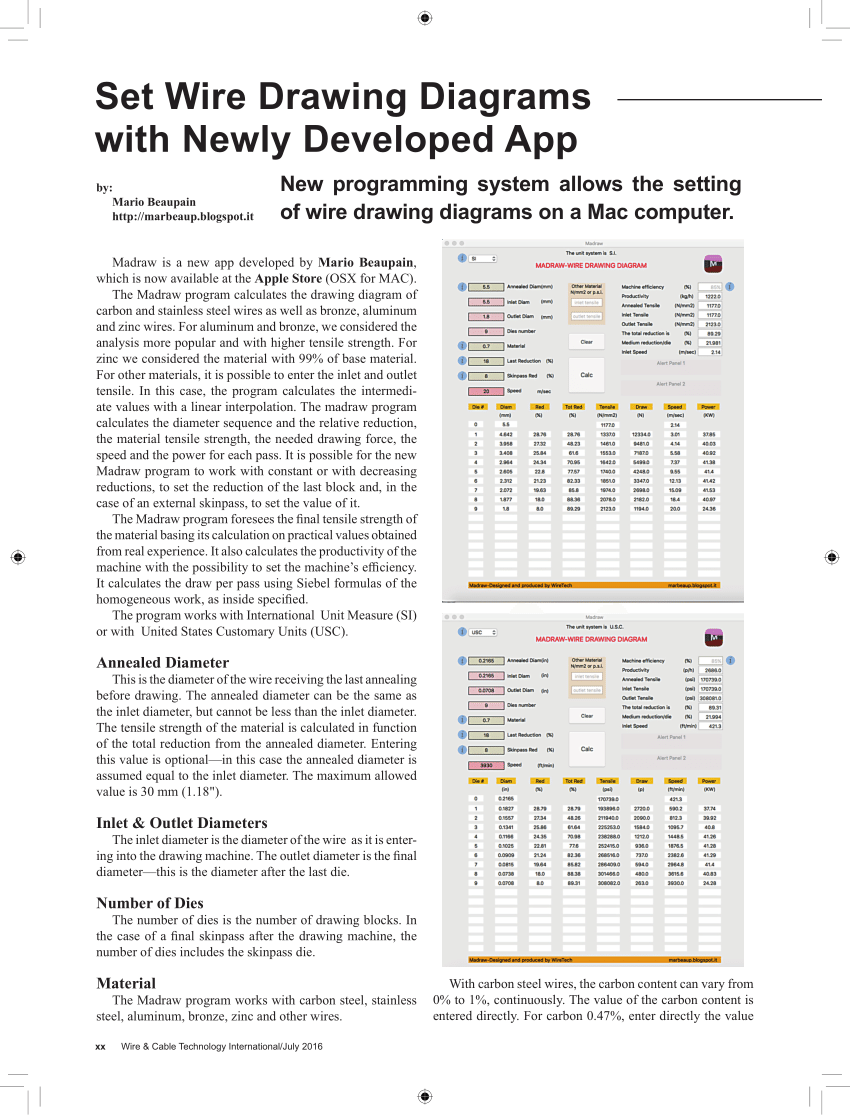

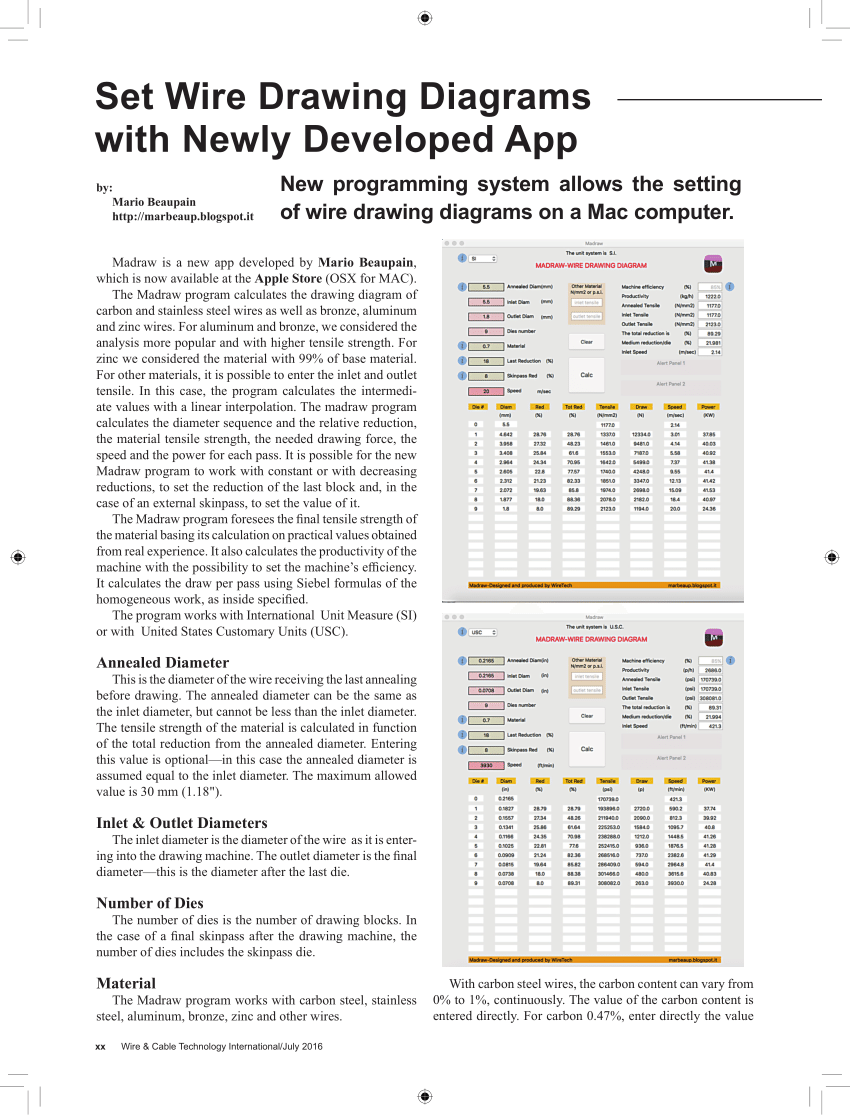

Wire drawing die Conical drawing die Shape of the bell causes hydrostatic pressure to increase and promotes the flow of lubricant into the die. A simple software App in Apple Store Mac OSX calculating all the wire drawing parameters as Reduction per pass tensile strength per pass draw needing power for different types of. Both the diameter size and the section of the wire are reduced.

If the size of the incoming wire is known. Ds ending wire. The velocity of the wire as it exits the last die can then be calculated by using Equation 2a as follows.

Fig 1 represents the die which has a conical-shaped bore with an outlet bearing land. Reduction is always positive. R n 2.

Rod drawing is similar process like wire drawing except it is rigid and has larger diameter compare to wire. For ferrous wire step reduction is usually between 7 and 38 limits depend on the product. The pulling force is limited by the strength of the material.

Minimum 00440 01118 Maximum 00396 01005 results in 236 -24 Nominal 00442 01123 Nominal 00394 01000 results in 260 Maximum 00444 01128 Minimum 00392 00995 results in 284 24 2. The force needed to pull the wire through. Dl beginning wire diameter.

Wire drawing reduction formula Coffin nails are becoming the hottest manicure trend right now which is likely nowhere quicklyBlack appears to be like fantastic with any colorHowever it doesnt make it any considerably less interesting. A draw reduction could involve two to 16 or more drawing operations. Wire drawing η 50 65 rolling η 60 80 Clearly the work formula method gives a lower band to the true force required for a given deformation processing operation because we are neglecting redundant work.

Dl beginning wire diameter. Drawn wire diameter mm inch A. D wire diameter.

Reduction in area is not additive r f is not f 1 r 2. The total die angle can have values between 5 and 25 and possible percentage reduction in area r of the wire vary between 10 and 50 percent. Ds ending wire diameter.

This process need heavier equipment compare to wire drawing because the wire can be coiled but a rod should be kept straight. If the size of the incoming wire is known. Wire Drawing Formulas D wire diameter Dl beginning wire diameter Ds ending wire diameter AR reduction in area N number of dies Df finished diameter of the die Bl bearing length A die angle Back A back relief angle.

Wire area reduction percentage Inversely the drawn wire diameter is calculated from the incoming wire diameter. Elongation of wire drawing. As the area reduction changes so does the die sequence.

D wire diameter. This increase is called Elongation. Df finished diameter of the die.

As the area reduction changes so does the die sequence. The area reduction in small wires is generally 1525 and in larger wires is 2045. B Schematic illustration of rigid and.

Having the right number of stations and the right diameters and heights is critical to the success of a multistage drawing process. A die angle. AR reduction in area.

Wire drawing consists of pulling a metal wire through a small circular opening called a die. Drawing process Before the actual drawing the material to be drawn is properly prepared. Bl bearing length.

Pull too hard and the metal will break. The incoming wire diameter is calculated from the drawn wire diameter for a given area reduction by using. For overall reduction greater than 85 the.

An increase of the wire length. Parameters include die angle a reduction in cross sectional area drawing speed temperature and lubrication For a certain reduction in diameter and friction conditions there is an optimum die angle. Area reduction r is defined as Ao-AfAo -----21 The drawing ratio R is defined as AoAf 11-r -----22 The important parameters which affect the wire drawing force are the drawing ratio die angle material flow stress friction etc.

If the linear speed of the pulling. The ideal work derive an expression for the maximum reduction in area per pass for a wire drawing operation for a material with a true-stress strain curve of σKεn Total work Ideal work frictional work redundant work Total work Ideal work 02 x Ideal work 12 x Ideal work Or Total work of deformation 12 u x volume. Area reduction A 1 -A 2 A 1.

This results in a stretching or elongation of the material along with a reduction in cross sectional area. The total die angle can have values between 5 and 25 and possible percentage reduction in area r of the wire vary between 10 and 50 percent where r 1 A2A1 100. Reduction is never larger than 100.

Calculation of lubricant film thickness between wire and die. 10 rows Wire Drawing Formulas. N number of dies.

The exact die sequence for a particular job is a function of area reduction input wire size and output wire size.

Wire And Rod Drawing Ppt Video Online Download

Die Science How To Perform A Draw Reduction

Wire And Rod Drawing Ppt Video Online Download

Matra Wire Drawing Diagram Calculator

Circular Wire Drawing Force Calculator Misstechietutor C Live Coding Help Online Technical Support

Pdf Drawing Diagram Setting On Wire Drawing Machines

Wire Drawing Process Reduction Ratio Of The Wire R Can Be Download Scientific Diagram

0 comments

Post a Comment