A Powder Transfer System conveys material vertically or horizontally to and. Ad Powder Coating For Manufacturers Fabricators Public in Marietta.

Vacuum Conveying For Pharma Applications Coperion

Pneumatic conveying systems are used to transfer bulk solids materials powder granule in pipes by using a gas most of the time air as the transport medium.

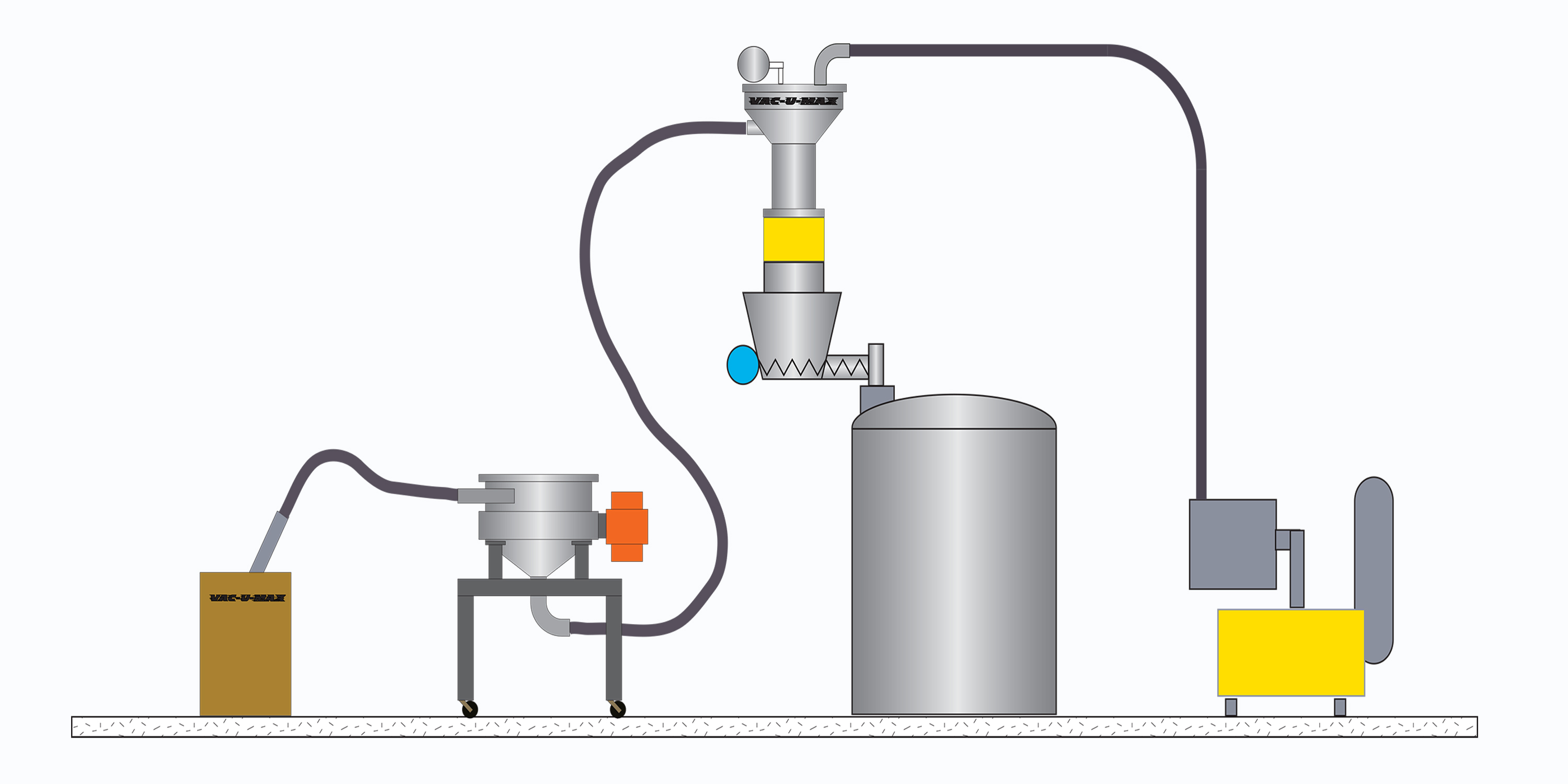

. The vacuum transfer system for powder comprises a suction device vessel with. Vacuum Conveying is the process of moving bulk dry materials such as powders from place to place within a factory using suction. Pneumatic conveying is by far the easiest method for transferring.

Powder transfer system design Talk about a refreshing and shiny design. Ad Young Industries Aero-Mechanical Conveyors Are Dust Tight For Conveying Fine Powders. Ideal For Transferring Powders From Bulk Bags Or Bag Dumping Systems Safe And Reliably.

The material is transferred in a network of tubing. Vacuum Conveying Systems are highly reliable. Very low maintenance and easily cleaned.

Transfer devices are other integral components for your powder handling needs. They are designed for contained products transfer out of bins to tablet presses encapsulators and. Extremely gentle to the material during transfer.

PTS Powder Transfer System can be equipped with the dosing device DosiValve allowing full integration into a packing or filling line to accurately dose powders into bags drums etc. How to select the suitable powder transfer system-Product characteristics and specifications- The first step to design a PTS is to understand the product which is required to be transferred. Quick and simple installation and control.

For dry bulk material applications which involve powder conveying many factors must be considered when designing a powder conveying. ALTOMECH Powder Transfer System conveying for the fast and contained transfer of powders granules flakes and pellets This systems are designed with High performance and Product. The custom system utilizes two low-profile.

Our powder transfer system moves food ingredients industrial powders and blends in a safe and clean manner with virtually no product separation or degradation. Powder Transfer System Design. Effective and reliable system for transfer of powders and granules Dust free operations Batch time reduction Time savings Manpower.

Vacuum conveying is an efficient solution that transfers powders granules and similar materials. When conveying dry bulk materials pneumatically the system designer has to also decide if the system is going to be a pressure system or a vacuum system. Our pneumatic powder conveying facilitates a reduction in batch time ensures total process integration.

One Of The Largest Powered Coating Firms In The SE. To maintain proper powder density in the auger filler heads standard equipment required customization to maintain product quality. This nail art injects a fun identity in you.

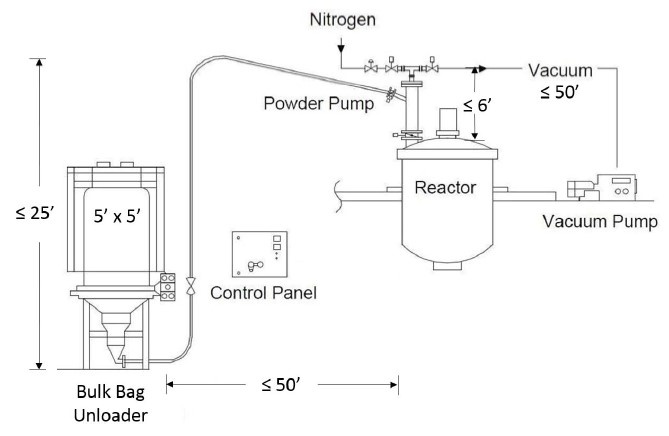

PWDER TRANSFER SSTEM 79 Benefits For You. Selecting the right powder conveyor is crucial in meeting your production goals in continuous applications. The Powder Pump is a dense-phase pneumatic conveying system that eliminates the need to manually handle solids and minimizes other potential hazards by providing a closed system to.

A variety of characteristics and particle sizes. With the light pinkish and white shades. Serving The Metal Industry Since 1989.

Powder Transfer Machine Pts Powder Transfer System Dec Group For The Pharmaceutical Industry

Powder Transfer System Powder Conveying System Powder Handling Systems Indpro

Powder Transfer System Offering Simplified Efficient Solutions

Vac U Max Vac U Max Vacuum Conveying Systems For Bulk Dry Powders

Technical Article Improving Powder Transfer Hanningfield

9 Things To Know When Specifying Vacuum Transfer Systems For Powders And Bulk Materials

0 comments

Post a Comment